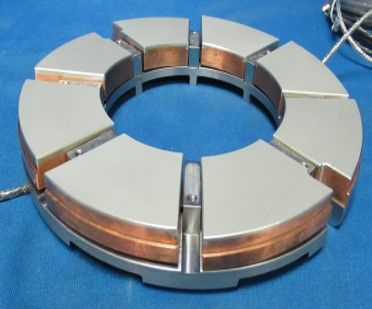

Mixers and agitators have a heavy load to carry – and they’re typically supported by only two bearings. Apart from the large load, these bearings must also be able to withstand a wide range of temperatures and chemicals.

Mixers and agitators have a heavy load to carry – and they’re typically supported by only two bearings. Apart from the large load, these bearings must also be able to withstand a wide range of temperatures and chemicals.

Hydrogen fluoride, or hydrofluoric acid, is often used in specialized chemical processes. That means hydrofluoric acid pumps need to work efficiently AND be able to withstand the presence of a strong acid.

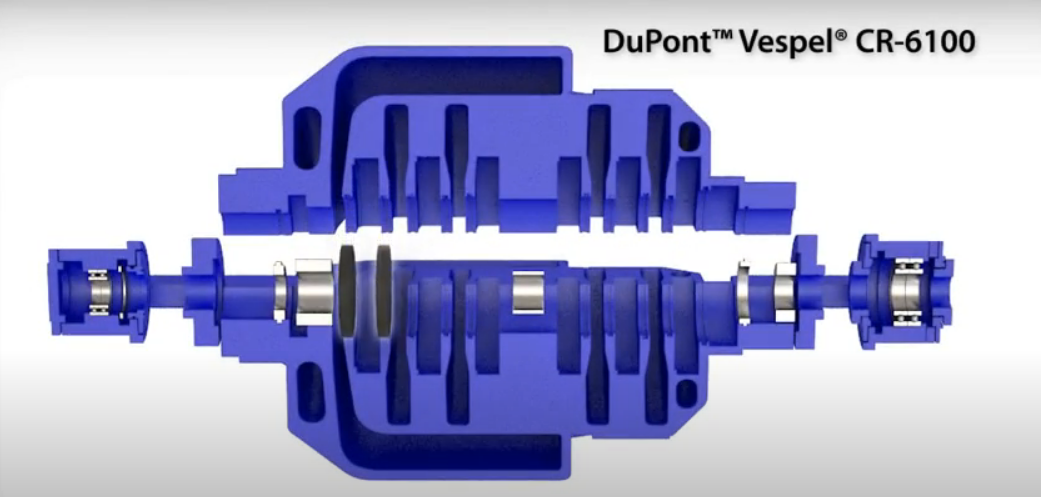

Switching to Vespel® CR-6100 may seem like a small change, but it can offer big results. After making this change with Boulden Company, a fertilizer plant in Canada eliminated pump seizures, was able to run at full capacity with one pump, could save their second pump for 100% spare capacity and saved over $30,000 in one year, which paid for the upgrade in just months.

We have exciting news! As part of our relentless pursuit of innovative solutions, Boulden has acquired Gulf Coast Bearing & Seal. This acquisition adds adjacent products and aftermarket service for turbomachinery to our solutions portfolio, so we can continue to offer long-term solutions that solve problems in the here and now. Welcome to the team, Gulf Coast Bearing & Seal!

Use DuPont™ Vespel® CR-6100 to make hydrofluoric acid pumps last longer Hydrofluoric acid—also known as HF acid or hydrogen fluoride—is a strong acid found in some refinery alkylation processes along with specialized chemical processes.

In every field, there are design numbers which indicate certain performance characteristics. For example, in the automotive world, the horsepower to weight ratio indicates how responsive a car might be. The pump world has its own set of terms which are used to...

Mixers and agitators typically have shafts 5 to 7 meters (15-20 feet) long with large propellers designed to mix the process fluid. The shafts are often supported by only two bearings—one at the top and one at the bottom. These bearings must withstand...

The shaft deflection in your pump directly affects mechanical seal reliability. Reducing wear ring clearance is an easy upgrade to minimize shaft deflection. Consider the faces of your mechanical seals–lapped flat to within one or two light bands of flatness, designed...

The 2-stage overhung pump is a common design from the 1960’s through the early 1980’s. Most plants built during that era will have at least a few of these pumps still running, and most likely causing problems. Upgrading the internal wear components with Vespel®...

An API separator is a piece of equipment typically found in oil refineries. It handles foul water from refinery process sewers and sends it to the treatment plant for processing. It also sends oil back to the coker for other reprocessing. This service contains...