BOULDEN PROVIDES LONG-TERM SOLUTION TO REPEAT FAILURES

Critical Machine Needs Frequent, Identical Repairs

A canned motor pump operating in a chemical plant on the Gulf Coast had a maximum uptime of only 12 weeks before needing repair. It was determined that the pump’s carbon bushings could not withstand the eroding properties of chlorine — the process fluid used in this particular pump. The rapid deterioration of the carbon bushings was not a total surprise. Though carbon fiber is resistant to chemical attack, it is not immune to all chemicals, particularly a chemical like chlorine.

The canned motor pump’s repeated failures caused a significant operational challenge to the chemical plant in the form of frequent repair costs and process disruption.

Boulden Provides a Better Than Ideal Solution

The plant’s repair facility and the customer had been considering Vespel® CR-6100 for several years as an upgrade to the carbon bushings. After the latest failure, it was time to make a change.

As eluded to above, when carbon fiber is exposed to chlorine, the chlorine reacts with the carbon atoms in the fibers to form chlorinated compounds. These compounds are less stable than the original carbon fibers and ultimately degrade strength and stiffness. One of the methods used to prevent this reaction is to coat the carbon fiber with Teflon®. DuPont™ Vespel® CR-6100 is a composite material manufactured from Teflon® PFA and carbon fiber. Due to its excellent dimensional stability, chemical resistance, and large temperature range, it was used to replace the pump’s carbon bushings to maximize its mean time between repair (MTBR).

An Exceptional Result…and Still Going

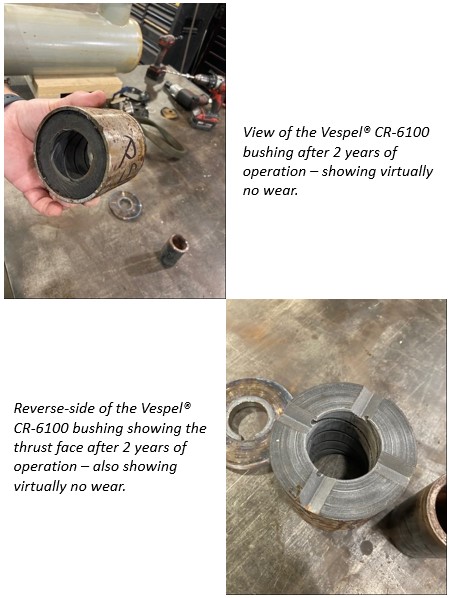

Boulden was able to maximize MTBR of the canned motor pump, extending its overall life dramatically and minimizing the risks of process disruption in the plant. After two years of continuous operation, the pump was taken out of service for an unrelated reason and the bushings were found to be within the OEM’s specifications.

Contact Boulden today to learn more about how our wear components and material solutions extend the life of high-value machines.