Increase Bearing Performance and Reliability in API Separators

An API separator is a piece of equipment typically found in oil refineries. It handles foul water from refinery process sewers and sends it to the treatment plant for processing. It also sends oil back to the coker for other reprocessing. This service contains hydrocarbons, water, acids, particles, amines and ammonia.

API SEPARATOR

The Challenge

Sleeve bearings support series of 21 foot (6.4m) long shafts in the 4 inch (101.6mm) diameter range. Unit size determines the number of shafts and some units are hundreds of feet long. The bearings drive skimmers and are historically babbitt or bronze. Greased bushings fail due to corrosion and contamination. Nickle-graphite bushings wear and score the shafts.

The Solution

Bearings machined from DuPont™ Vespel® CR-6100 increase performance and reliability and reduce failures to extend life and lower maintenance costs. Vespel® CR-6100 can operate without lubrication because of its low wear and low coefficient of friction. The composite nature of Vespel® CR-6100 allows for less damage to the shaft at contact which extends the life of the equipment. In addition, its chemical resistance allows for operation in the most diverse aggressive services.

Metal impregnated graphite Vespel® CR-6100

3.5 year service 3.5 year service

0.5” (12.7mm) 0.02” (0.51mm)

Wear, shaft damage Wear, NO shaft damage

Not serviceable Serviceable

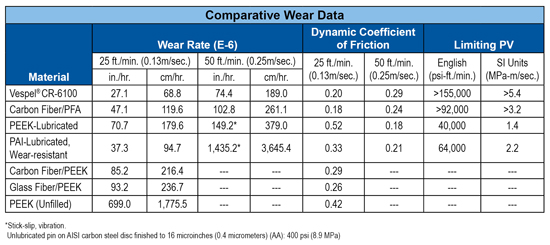

This comparative wear data chart shows the superior characteristics of Vespel® CR-6100 as compared to other, traditional materials used for bearings in API separators.