STRIPPER BOTTOMS PUMP RELIABILITY IMPROVEMENT

A Pump on the Bad Actors List

A refinery wanted to improve the stripper bottoms pump in their de-ethanizer unit. The pump is an API Type BB2 (single-stage, between-bearings, radially split configuration) originally supplied in 1971. The product is a low specific gravity hydrocarbon at 220⁰ F (105⁰ C) with the pump running at 3,570 rpm.

The pump had suffered chronic failures for many years. The typical failure modes were seal leaks or bearing failures. A look at the records showed maintenance events every 5-12 months and very high costs. The plant engineer had worked with Boulden on many previous pump upgrades and thought this pump was a good candidate for composite wear rings. The original metal wear rings in the pump ran with 0.030—0.033” (0.76—0.84 mm) clearance—compared to 0.019” (0.48 mm) recommended API clearance. The pump also had a relatively long, thin shaft. During operation, long, thin shafts can allow excessive deflection at the mechanical seal, leading to seal failures. At a minimum, the engineer thought if he could reduce the wear ring clearance, it would help the seals and bearings last a bit longer.

An Ideal Candidate for a Composite Upgrade

Boulden agreed with the engineer that this was an ideal candidate. The fact that the clearance was set significantly larger than API clearance suggested that the pump probably suffered from seizure in the past. With metal rings, the typical method of avoiding seizure is to increase the clearance. However, larger clearances lead to more shaft deflection, higher vibration and shorter life for the seals and bearings.

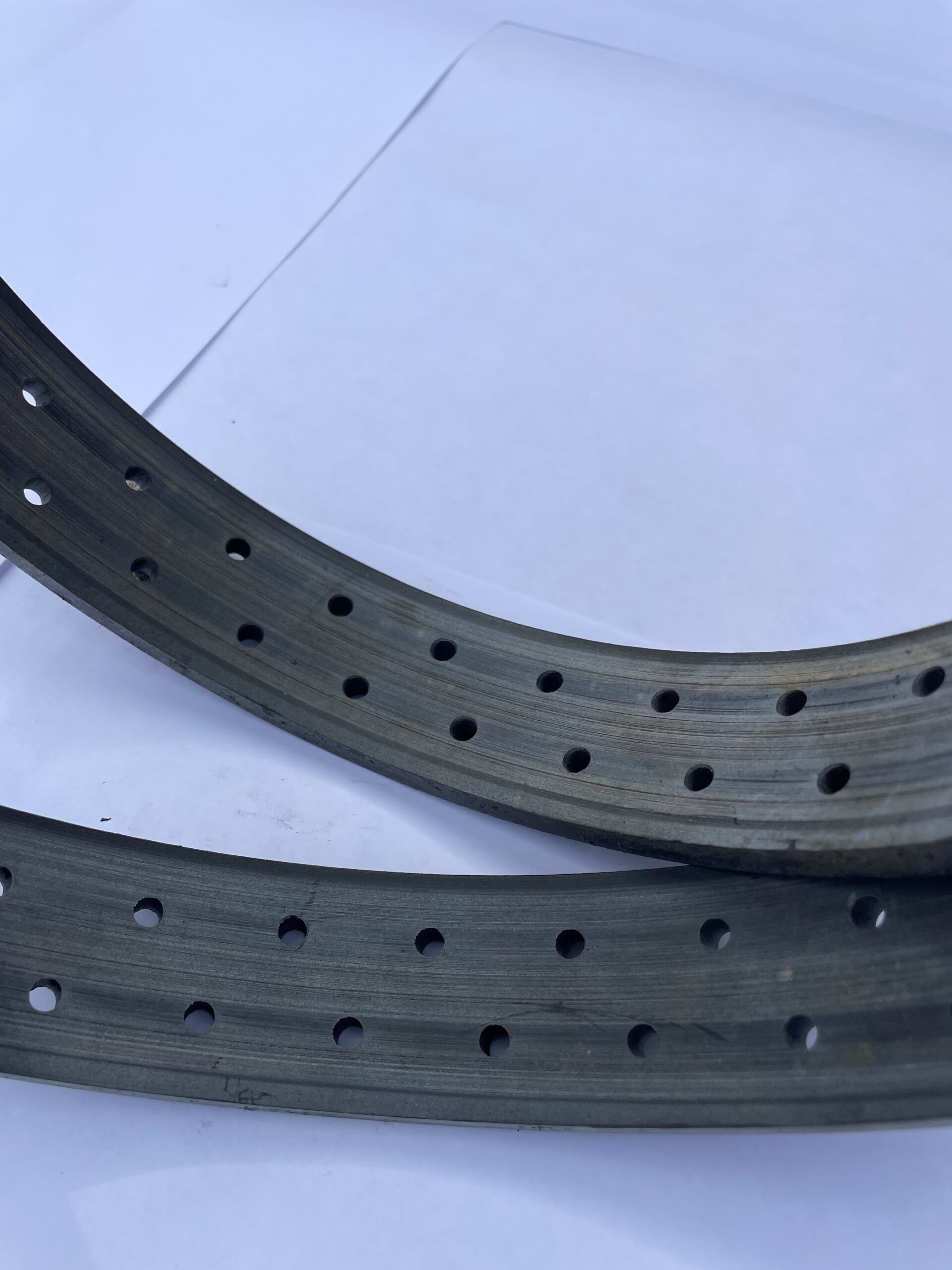

Boulden recommended Vespel® CR-6100 wear rings with the Boulden PERF-Seal® design. The service conditions were well within the capabilities of Vespel® CR-6100 and the material was already in use on site. The non-seizing, non-galling, dimensionally stable Vespel® CR-6100 allowed the wear ring clearance to be reduced to 0.010”. The pattern of holes in the PERF-Seal® design would further improve the rotor stability.

A Positive Outcome

The pump was overhauled in 2018 and put back into service. It ran without issues until May 2023. The image to the right shows the wear rings as found after 5 years of operation with minimal wear. The clearance had only increased by 0.005—0.007” (0.12—0.17 mm) from the “as installed” value 5 years earlier. One simple change took the pump from the bad actors list to 5 years of running without failure.

If you have a pump that is causing you chronic headaches, contact Boulden today.