REDUCE PUMP VIBRATION

Why Vespel® CR-6100 Reduces Pump Vibration

With Vespel® CR-6100, you can reduce the clearance at the pump wear components. For many pump designs, this change will significantly reduce the overall pump vibrations.

The wear rings in the pump have a significant impact on rotor stability, especially for pump designs with long, slender shafts. Excessive wear ring clearance can lead to high vibration, loss of rotor stability, and even the potential for high-energy failure modes such as shaft breakage.

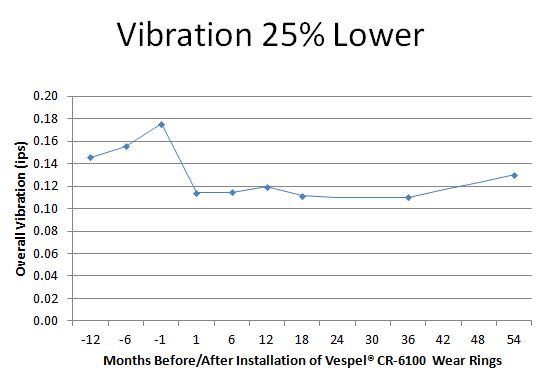

Conversely, reducing the wear ring clearance improves rotor stability and lowers the overall vibration level of the pump. In a long-term study of Vespel® CR-6100, the vibration data for 25 pumps was tracked for one year before the conversion to Vespel® CR-6100 with reduced clearance and 4.5 years after the conversion.

Figure 1 shows the trend from before and after the conversion. The average reduction in vibration levels was 25%, and the reduction was maintained over 4.5 years after the conversion to Vespel® CR-6100. For some pumps, the reduction in wear ring clearance produced a vibration reduction near 50%. For pumps which were already running at a very low vibration level (<0.1 in/sec), the reduction in clearance did not produce a reduction in vibration.

What to do to Reduce Pump Vibration with Vespel® CR-6100

- Replace the stationary wear rings with Vespel® CR-6100

- Continue using metal rotating wear rings

- Reduce the wear ring clearance to 50% of the API recommended minimum

Vibration reduced by 25% after the pumps were installed with Vespel® CR-6100.

Benefits of Vespel® CR-6100 when Reducing Pump Vibration

- Lower vibration levels

- Improved rotor stability

- Reduced shaft deflection at the mechanical seals

- Higher efficiency

- Lower risk of cavitation

Learn More About Vespel® CR-6100

Learn more about Vespel® CR-6100 and its many uses by checking out our composite pump components and Vespel® CR-6100. Discover how composites have improved other pump performance be check out our case studies.