ABRADABLE SEALS

Summary

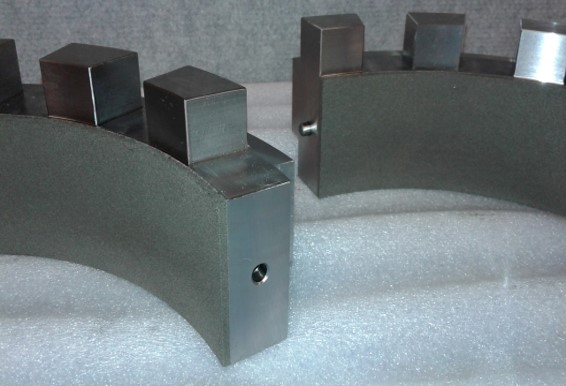

If you are looking for a supplier of abradable seals for your centrifugal compressor, our team at GCBS (Gulf Coast Bearing and Seal) can help. We fabricate abradable seals from Fluorosint and Nickel Graphite up to 1 meter (40”) diameter. If you need quality components with fast response, contact Boulden today.

Background

Abradable seals can run with tighter clearance than traditional stationary aluminum labyrinth seals. The tighter clearance results in higher compressor efficiency. For most compressor makes and models using abradable seals, rotating labyrinths are installed at the impeller eyes and between impellers. A soft “abradable” material—usually Fluorosint or Nickel Graphite—is used for the stationary wear component. During transient conditions such as passing through a critical speed at start up, the rotating labyrinths will simply cut a channel into the abradable material, avoiding damage to the labyrinths and allowing the compressor to continue operation with tight clearance and high efficiency.

Our team at GCBS has decades of experience manufacturing abradable seals in Fluorosint and Nickel Graphite. Fluorosint is generally used in lower temperature applications with Nickel Graphite applied where higher temperature capability is needed.

Key Benefits of Abradable Seals

- Design allows tighter running clearance

- Result of tighter clearance is higher compressor flow or efficiency

- Tolerant of transient contact at start-up without damage to labyrinth teeth

- Resistance to most process chemicals

- Some abradable materials capable of very high temperatures

Difference Between Abradable Seals and Thermoplastic Labyrinth Seals

Sometimes, abradable seals are discussed in the same context as thermoplastic labyrinth seals—sometimes referred to as “rub tolerant” seals. While the two approaches deliver similar results, they are quite different in application.

What is an Abradable Material?

First, it is important to understand what is meant by “abradable”. Look in the dictionary and it says, “capable of being abraded.” Look up “abraded” and you find that it means the material can be worn down or scraped away by contact. So, an abradable material is a sacrificial material that will cut away with contact.

Therefore, an abradable seal survives transient contact by allowing the straight labyrinth teeth to cut a groove in the soft, abradable material. This tolerance of contact allows the compressor to run with tight clearances at the labyrinth and achieve higher efficiency.

What are Thermoplastic Labyrinth Seals?

The big difference between the two approaches is in application. If your compressor was originally designed with stationary aluminum labyrinths, converting to thermoplastic labyrinth seals is a simple, straightforward upgrade. The new thermoplastic labyrinth seals will be drop-in replacements for the original aluminum seals, generally with no other machine modifications required.

Converting from stationary aluminum labyrinths to abradable seals, however, can be a significant engineering project. This type of conversion generally requires rotor modifications, associated rotor-dynamic analysis, and design of new abradable seals. To optimize your compressor efficiency, we recommend the following labyrinth seal designs:

Original Labyrinth Seal Design

Recommended Labyrinth Seals

Stationary Aluminum Seals

Upgrade to Thermoplastic Labyrinth Seals

Abradable Seals

Continue Using Abradable Seals

Whether your compressor uses abradable seals or thermoplastic labyrinth seals, both approaches offer efficiency gains compared to traditional aluminum labyrinth seals. The tighter clearance reduces losses at the impeller eyes and shaft seals between stages—where high pressure gas leaks across the seals to the previous compressor stage. Reducing this leakage increases compressor efficiency and increases potential throughput.

Manufacturing Excellence

We manufacture abradable seals at our GCBS facility in Houston. We use modern CNC machines to produce parts with exceptional accuracy and precision. Our team is made up of turbomachinery professionals who have decades of experience working with fertilizer plants, petrochemical facilities, refineries, and gas plants. Whether your machine is an air compressor or ethylene compressor, we understand the service conditions involved, the importance of the machine to your operations.

Beyond simply fabricating the parts, however, our team at GCBS can help analyze your design and make improvements to make your compressors more reliable. For example, we have seen Fluorosint abradable seals damaged in higher temperature applications. While Fluorosint is a good abradable material, it is not particularly strong at elevated temperatures. We can re-design these seals to be stronger and more resilient. If you are having any issues with abradable seals, contact Boulden today.

If you want a reliable supplier of centrifugal compressor labyrinth seals, contact Boulden today. If you have existing aluminum labyrinth seals, talk to us about an upgrade to thermoplastic labyrinth seals. If you have abradable seals, our team at GCBS has decades of experience working with the most common abradable materials. Contact us today for a consultation.