Boulden’s objective is to help plant engineers with solutions they can use to improve the reliability, efficiency, and safety of their machines.

Vespel CR-6100

Serving: North America, Europe, Middle East, Africa, Singapore, Australia, New Zealand

B-Series

Available Globally

Perf-Seal

Available Globally

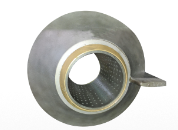

Pump Components

Available Globally

Pump Improvements

Available Globally