Ethane and methane are the lightest light hydrocarbons. In liquid form, they are most commonly found at cryogenic temperatures down to -160⁰C. The cryogenic temperatures combined with the low viscosity and flashing nature of the products makes cryogenic ethane, methane, and LNG pumps a challenging pump application.

Limitations of traditional materialsThe wear rings in a typical cryogenic LNG pump are often 316L stainless steel, and shaft bushings are often carbon-filled PTFE. Both

materials are fine with the product and low temperatures, but they require tough design trade-offs.316L parts require generous clearances to avoid seizure. Larger clearances increase the risk of cavitation and vaporization of the product at suction. Carbon-filled PTFE is a good cryogenic material, but it lacks dimensional stability. If a pump runs dry in this service, the carbon-filled PTFE bushings will be destroyed quite quickly.

Vespel® CR-6100 is an ideal material for cryogenic LNG serviceVespel® CR-6100 is a composite material made from long, oriented carbon fibers and Teflon® PFA resin. It provides excellent performance

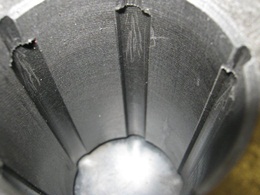

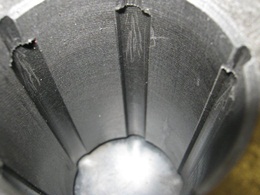

in cryogenic temperatures, but also delivers exceptional dimensional stability. Using Vespel® CR-6100, wear ring clearances can be reduced to less than the API 610 minimum standard for metal wear rings, and shaft bushings will run for many years. If the light methane or ethane gas evaporates at suction, the pump will not have metal-to-metal contact points, and the risk of seizure will be minimized.Photos 1 and 2 show the shaft bearing and case wear ring from a single stage liquid methane pump running at -82⁰C. The pump was removed for inspection after 4 months of running because it appeared as though the pump had run dry due to operational issues. Upon inspection, the parts were found in “as installed” condition and the pump returned to service.

Ethane and methane are the lightest light hydrocarbons. In liquid form, they are most commonly found at cryogenic temperatures down to -160⁰C. The cryogenic temperatures combined with the low viscosity and flashing nature of the products makes cryogenic ethane, methane, and LNG pumps a challenging pump application.Limitations of traditional materialsThe wear rings in a typical cryogenic LNG pump are often 316L stainless steel, and shaft bushings are often carbon-filled PTFE. Both

materials are fine with the product and low temperatures, but they require tough design trade-offs.316L parts require generous clearances to avoid seizure. Larger clearances increase the risk of cavitation and vaporization of the product at suction. Carbon-filled PTFE is a good cryogenic material, but it lacks dimensional stability. If a pump runs dry in this service, the carbon-filled PTFE bushings will be destroyed quite quickly. Vespel® CR-6100 is an ideal material for cryogenic LNG serviceVespel® CR-6100 is a composite material made from long, oriented carbon fibers and Teflon® PFA resin. It provides excellent performance

Ethane and methane are the lightest light hydrocarbons. In liquid form, they are most commonly found at cryogenic temperatures down to -160⁰C. The cryogenic temperatures combined with the low viscosity and flashing nature of the products makes cryogenic ethane, methane, and LNG pumps a challenging pump application.Limitations of traditional materialsThe wear rings in a typical cryogenic LNG pump are often 316L stainless steel, and shaft bushings are often carbon-filled PTFE. Both

materials are fine with the product and low temperatures, but they require tough design trade-offs.316L parts require generous clearances to avoid seizure. Larger clearances increase the risk of cavitation and vaporization of the product at suction. Carbon-filled PTFE is a good cryogenic material, but it lacks dimensional stability. If a pump runs dry in this service, the carbon-filled PTFE bushings will be destroyed quite quickly. Vespel® CR-6100 is an ideal material for cryogenic LNG serviceVespel® CR-6100 is a composite material made from long, oriented carbon fibers and Teflon® PFA resin. It provides excellent performance in cryogenic temperatures, but also delivers exceptional dimensional stability. Using Vespel® CR-6100, wear ring clearances can be reduced to less than the API 610 minimum standard for metal wear rings, and shaft bushings will run for many years. If the light methane or ethane gas evaporates at suction, the pump will not have metal-to-metal contact points, and the risk of seizure will be minimized.Photos 1 and 2 show the shaft bearing and case wear ring from a single stage liquid methane pump running at -82⁰C. The pump was removed for inspection after 4 months of running because it appeared as though the pump had run dry due to operational issues. Upon inspection, the parts were found in “as installed” condition and the pump returned to service.

in cryogenic temperatures, but also delivers exceptional dimensional stability. Using Vespel® CR-6100, wear ring clearances can be reduced to less than the API 610 minimum standard for metal wear rings, and shaft bushings will run for many years. If the light methane or ethane gas evaporates at suction, the pump will not have metal-to-metal contact points, and the risk of seizure will be minimized.Photos 1 and 2 show the shaft bearing and case wear ring from a single stage liquid methane pump running at -82⁰C. The pump was removed for inspection after 4 months of running because it appeared as though the pump had run dry due to operational issues. Upon inspection, the parts were found in “as installed” condition and the pump returned to service.