METCAR® M-310

Metcar® M-310 is carbon graphite impregnated with nickel-chrome alloy. M-310 is the highest temperature composite material and can be used in temperatures from cryogenic to 1700 F (900 C). The nickel impregnation provides excellent strength, heat dissipation, and chemical resistance.

Benefits of Upgrading Pump Components to M-310

Metcar® M-310 has a combination of low-friction, high strength, high-temperature limit, and excellent heat dissipation. It is completely non-seizing and non-galling and can run dry during pump start-up and through typical process conditions which would damage traditional materials. M-310 has excellent dimensional stability and a low coefficient of thermal expansion, allowing precise tolerances on your critical parts. Bearings that would otherwise require oil or grease can often be upgraded to M-310 eliminating the need for external lubrication. M-310 is a great choice for the following components:

- Mag-drive or canned-motor pump bearings

- Pump wear rings

- Agitator bearings

- Vertical pump shaft bearings

- Non-lubricated bearings

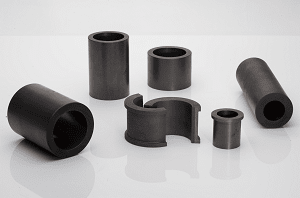

Metcar® Carbon Graphite Grooved Bearings

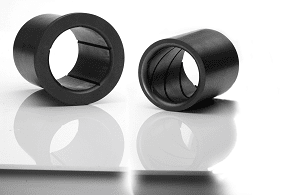

Metcar® Carbon Graphite Bearings

Boulden can supply M-310 raw material standard sizes up to 6” (152.4 mm) diameter are available with short lead times. Custom sizes with larger diameters can be ordered with a longer delivery. Machined parts made to order can also be supplied. We can assist with all design details to provide Metcar parts custom-made for you. Contact Boulden today and we will help you make your machines more reliable, safe, and efficient. Visit the Metcar® site for additional Nickel Rod Stock M-310 Specification info.