Hot Water Condensate Pumps: Upgrade with DuPont™ Vespel® CR-6100

Condensate return pumps often cause reliability problems. Hot water can vaporize, causing pumps to run dry. Hot water is also a notoriously poor lubricant, resulting in excessive wear of traditional materials. Vespel® CR-6100 has been used in dozens of condensate pumps over the years with excellent results. The first known pump to be upgraded to Vespel® CR-6100 was a condensate pump in a refinery, and this simple upgrade increased the MTBR of the pump from 4 months to 9 years.

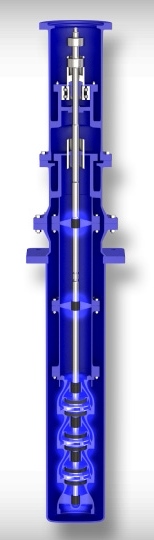

The first pump upgraded with Vespel® CR-6100

The first pump upgraded with Vespel® CR-6100

In 1997, the condensate return pump at a California refinery was unreliable, failing due to run-dry events. Plant personnel had tried all types of different materials—the original bronze, metal alloys, plastics, and even ceramic bearings. Nothing worked. The pumps would fail three times per year.

The plant engineers decided to try Vespel® CR-6100 in this application due to its low coefficient of thermal expansion, believing this could help the pump survive run dry events. They installed Vespel® CR-6100 shaft bearings and stationary wear rings.

Because this was likely the first pump in the world to use Vespel® CR-6100, they ran a test. While monitoring motor amps and vibration, they deliberately ran the pump dry for progressively longer periods of time. When the pump survived running dry for 30-minutes, they turned the pump over to operations, and shortly thereafter upgraded the other pump in the service.

For several years after this installation, the pumps ran without failure.

Epilogue

At a turnaround 3 years after the initial installation, one of the pumps was pulled for inspection. The Vespel® CR-6100 remained in excellent condition with nearly zero wear. The pump was reassembled and returned to service. In 2006, the refinery engineers took a look at the maintenance records of the pumps and found that neither pump had been overhauled since the original installation of Vespel® CR-6100. The MTBR of the pumps had increased from 4 months to 9 years.

Over the past 15 years, thousands of pumps have been upgraded with Vespel® CR-6100 with excellent results. Due to successful applications around the world, Vespel® CR-6100 is now included in API610 11th Edition—the global standard for centrifugal pumps in the hydrocarbon processing industry.